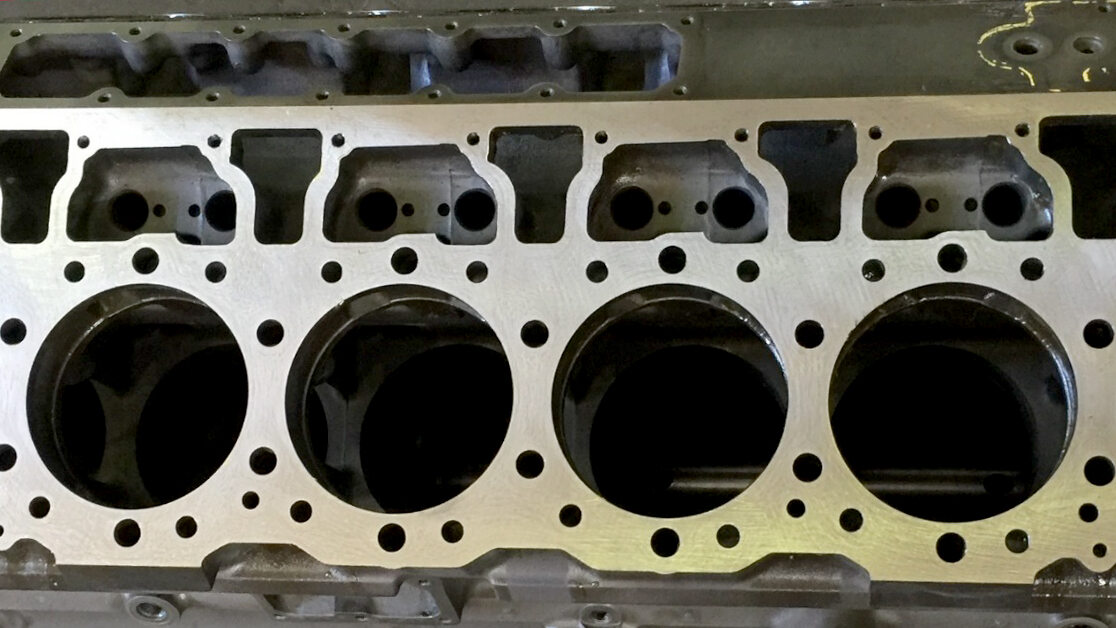

Engine cylinder liner and piston ring are a pair of friction pairs that work under high temperature, high pressure, alternating load and corrosion. Working in complex and changeable conditions for a long time, the result is that the cylinder liner is worn and deformed, which affects the power, economy and service life of the engine. It is very important to analyze the causes of cylinder liner wear and deformation for improving the economy of engine.

1. Cause analysis of cylinder liner wear

The working environment of the cylinder liner is very bad, and there are many reasons for wear. Normal wear is usually allowed due to structural reasons, but improper use and maintenance will cause abnormal wear.

1 Wear caused by structural reasons

1) The lubrication condition is not good, so that the upper part of the cylinder liner wear seriously. The upper part of the cylinder liner is adjacent to the combustion chamber, the temperature is very high, and the lubrication condition is very poor. The erosion and dilution of fresh air and unevaporated fuel aggravate the deterioration of the upper condition, so that the cylinder is in a state of dry friction or semi-dry friction, which is the cause of serious wear on the upper cylinder.

2) The upper part is under large pressure, so that the cylinder wear is heavy on the upper and light on the lower. The piston ring is pressed tightly on the cylinder wall under the action of its own elasticity and back pressure. The greater the positive pressure, the more difficult the formation and maintenance of lubricating oil film, and the worse the mechanical wear. In the work stroke, as the piston goes down, the positive pressure gradually decreases, so the cylinder wear is heavy up and light down.

3) Mineral acids and organic acids make the cylinder surface corroded and spalling. After the combustion of the combustible mixture in the cylinder, water vapor and acid oxides are produced, which dissolve in water to produce mineral acids, plus the organic acids generated in the combustion, which have a corrosive effect on the surface of the cylinder, and the corrosive substances are gradually scraped off the piston ring in the friction, resulting in cylinder liner deformation.

4) Enter the mechanical impurities, so that the middle of the cylinder wear. Dust in the air, impurities in the lubricating oil, etc., enter the piston and cylinder wall causing abrasive wear. When dust or impurities reciprocate in the cylinder with the piston, the movement speed is the largest in the middle of the cylinder, which aggravates the wear in the middle of the cylinder.

2 Wear caused by improper use

1) The filter effect of lubricating oil filter is poor. If the lubricating oil filter is not working properly, the lubricating oil can not be effectively filtered, and the lubricating oil containing a large number of hard particles will inevitably aggravate the wear of the inner wall of the cylinder liner.

2) Low filtration efficiency of air filter. The role of the air filter is to remove dust and sand particles contained in the air entering the cylinder to reduce the wear of the cylinder, piston and piston ring parts. The experiment shows that if the engine is not equipped with air filter, the wear of the cylinder will increase by 6-8 times. The air filter is not cleaned and maintained for a long time, and the filtration effect is poor, which will accelerate the wear of the cylinder liner.

3) Long-term low temperature operation. Running at low temperature for a long time, one is to cause poor combustion, carbon accumulation starts to spread from the upper part of the cylinder liner, causing serious abrasive wear on the upper part of the cylinder liner; The second is to cause electrochemical corrosion.

4) Often use inferior lubricating oil. Some owners in order to save money, often in roadside shops or illegal oil sellers to buy inferior lubricating oil to use, resulting in strong corrosion of the upper cylinder liner, its wear is 1-2 times larger than the normal value.

3 Wear caused by improper maintenance

1) Improper cylinder liner installation position. When installing the cylinder liner, if there is an installation error, the cylinder center line and the crankshaft axis are not vertical, it will cause abnormal wear of the cylinder liner.

2) Connecting rod copper hole deviation. In the repair, when the connecting rod small head copper sleeve is hinged, the reamer tilt causes the connecting rod copper sleeve hole to be skewed, and the center line of the piston pin is not parallel to the center line of the connecting rod small head, forcing the piston to tilt to one side of the cylinder liner, which will also cause abnormal wear of the cylinder liner.

3) Connecting rod bending deformation. Due to car accidents or other reasons, the connecting rod will bend and deform, and if it is not corrected in time and continues to be used, it will also accelerate the wear of the cylinder liner.

2. Measures to reduce cylinder liner wear

1. Start and start correctly

When the engine starts cold, due to low temperature, large oil viscosity and poor fluidity, the oil pump is insufficient. At the same time, the oil on the original cylinder wall flows down the cylinder wall after stopping, so the lubrication is not as good as that in normal operation at the moment of starting, resulting in a great increase in the wear of the cylinder wall when starting. Therefore, when starting for the first time, the engine should be idled for a few laps, and the friction surface should be lubricated before starting. After starting, idle operation should be heated up, it is strictly prohibited to blast the oil port, and then start when the oil temperature reaches 40℃; Start should adhere to the low-speed gear, and step by step each gear to drive a distance, until the oil temperature is normal, can turn to normal driving.

2. Correct selection of lubricating oil

To strictly according to the season and engine performance requirements to choose the best viscosity value of the lubricating oil, can not be purchased at will with inferior lubricating oil, and often check and maintain the quantity and quality of lubricating oil.

3. Strengthen the maintenance of the filter

Keeping the air filter, oil filter and fuel filter in good working condition is crucial to reducing the wear of the cylinder liner. Strengthening the maintenance of the "three filters" is an important measure to prevent mechanical impurities from entering the cylinder, reduce cylinder wear, and extend the service life of the engine, which is particularly important in rural and sand-prone areas. It is absolutely wrong that some drivers do not install air filters in order to save fuel.

4. Keep the engine at normal operating temperature

The normal operating temperature of the engine should be 80-90 ° C. The temperature is too low and can not maintain good lubrication, which will increase the wear of the cylinder wall, and the water vapor in the cylinder is easy to condense into water droplets, dissolve acidic gas molecules in the exhaust gas, generate acidic substances, and make the cylinder wall subject to corrosion and wear. The test shows that when the cylinder wall temperature is reduced from 90℃ to 50℃, the cylinder wear is 4 times that of 90℃. The temperature is too high, it will reduce the strength of the cylinder and aggravate the wear, and may even cause the piston to overexpand and cause the "cylinder expansion" accident.

5. Improve warranty quality

In the process of use, problems are found in time to be eliminated in time, and damaged and deformed parts are replaced or repaired at any time. When installing cylinder liner, check and assemble strictly according to technical requirements. In the warranty ring replacement operation, the piston ring with appropriate elasticity should be selected, the elasticity is too small, so that the gas breaks into the crankcase and blows the oil on the cylinder wall, increasing the cylinder wall wear; Excessive elastic force directly aggravates the wear of the cylinder wall, or the wear is aggravated by the destruction of the oil film on the cylinder wall.

Crankshaft connecting rod journal and main shaft journal are not parallel. Due to burning tile and other reasons, the crankshaft will be deformed by severe impact, and if it is not corrected in time and continues to be used, it will also accelerate cylinder liner wear.

Post time: Jul-30-2024